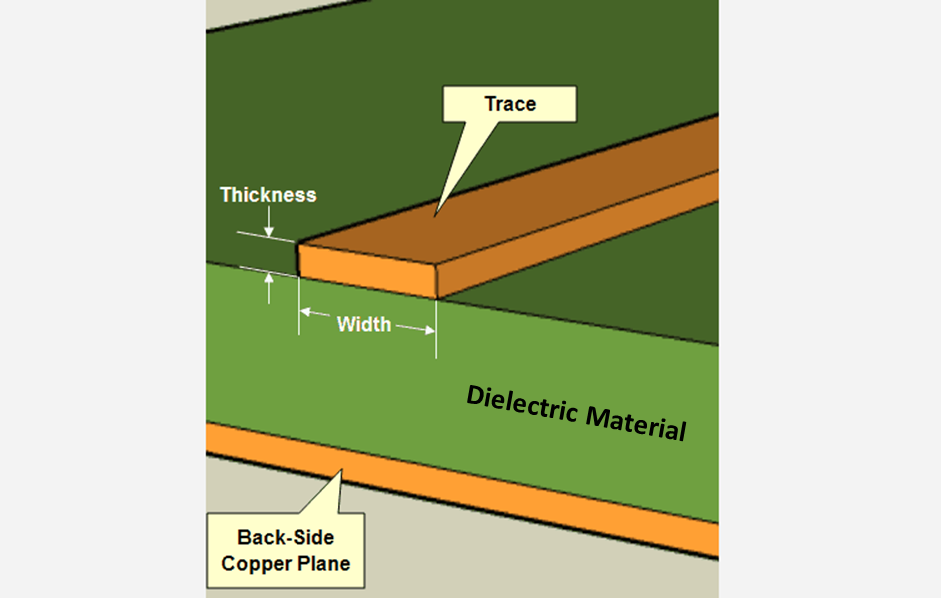

If you have a multi-layer PCB with a copper plane near your conductor, the actual ∆T will be substantially lower. Calculations based on these data should fit most assemblies and here will be referred to as universal or generic. For example, for i=10A and ∆T=20 oC the IPC gives Ac=500, while our formula yields 513.1, which is within 3% accuracy. The above equation provides reasonably accurate approximation of the generic Fig.5-2 charts. Once you determined Ac, you can find the required trace width for a given copper weight: width=Ac/thickness, where thickness(mil)=oz/1.3.

For this I have interpolated K1(∆T) and K2(∆T) between 2 and 100 oC by using a curve fit function that employs least-squares power curve regression. I thought it would be convenient to have a unified formula for cross-sectional area as a function of electric current, so we could quickly find it for any arbitrary ∆T. Note that both the multiplier K1 and the exponent K2 vary depending on ∆T. I would like to thank Jack for allowing me to utilize his numbers. Jack Olson from Caterpillar has calculated these and other coefficients and provided them in his spreadsheet and a related article. For a selected ∆T one can derive K1 and K2 by estimating the slope and intercept point of an appropriate plot in Fig.5-2. This means that: Ac(i)=K1×i K2, where K1 and K2 are some constants.

We know that a straight line on log-log graph represents a polynomial.

They are given for certain discrete values of temperature rise and they all are linear in logarithmic scales. Ac charts for the polyimide boards 0.070" thick with 3 ounce copper in still air. We will use IPC-2152 Figure 5-2, which represents a typical application.

0 kommentar(er)

0 kommentar(er)